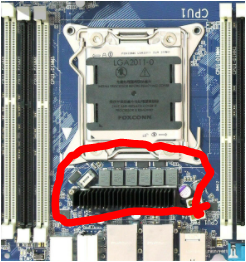

For my current liquid cooled rig (9600KF) I found that building in a tool-less design with the radiators themselves can be helpful when you have to constantly go back into the loop to perform maintenance or upgrades / modifications, etc. I have about 1000mm of standard radiator cooling in this rig (plus a 60 plate liquid to liquid heat exchanger for the chiller), which is plenty for a hexacore like this, but for benching, especially cold weather stuff, I like the ease of use to disassemble / assemble the cooling system.. it's always a whole lot easier if you can set the other radiators out of the way for a minute. . This is because all the radiators are tension fit and can be pulled completely out of the case before you have to disconnect them. Now it's not earthquake rated but it could probably fair better than the Fukushima Daichi nuclear power plant did!

Point being I can remove the radiators from the case itself, the rads I want to work on easily, tilt the case on it's side and then even if I spill something it's not going to leak on the motherboard. I left the lines long enough to do this, and while it's still a PITA and can lead to a mess on occasion, it's much better than having all your rads bolted into place, because then you are at the mercy of their location within the case and whether you are feeling lucky that day. I also use a small vice grip to eliminate or mitigate the leak once I disconnect a line. Anyway, just thought I would share want's been working out ok for me so far.

here is a picture and you can see both the 360mm on the bottom and the 240mm above it both have a tension fit, making it very easy to work on the cooling system itself by removing the rad from the rig before disconnecting the lines. You think 3 pumps and two reservoirs here is a little overkill? lol you can never have enough flow! All the radiators come out of the rig in less than one minute.