Welcome to ExtremeHW

Welcome to ExtremeHW, register to take part in our community, don't worry this is a simple FREE process that requires minimal information for you to signup.

Registered users can:

- Start new topics and reply to others.

- Show off your PC using our Rig Creator feature.

- Subscribe to topics and forums to get updates.

- Get your own profile page to customize.

- Send personal messages to other members.

- Take advantage of site exclusive features.

- Upgrade to Premium to unlock additional sites features.

-

Posts

335 -

Joined

-

Last visited

-

Days Won

6 -

Feedback

0%

Content Type

Forums

Store

Events

Gallery

Profiles

Videos

Marketplace

Tutorials

Everything posted by ArchStanton

-

@Bastiaan_NL So, 7,830,000mm³ of radiator for just the CPU, "Big Boy" tubing, and a power supply that will trip a 15-amp circuit breaker if your electrician cut any corners. Fun times! BTW, that is some of the fastest rated DDR5 I have seen out in the wild, but I have not been following that market closely.

-

Well, I wasn't quite able to complete the reassembly this weekend. Made some good progress though. Will continue working on it in the evenings as my schedule at work allows (we are transitioning from the "winter break" to "full speed ahead" as temperatures rise). I've made quite a few changes to the loop (will detail them in subsequent posts). One of these changes is the inclusion of a filter. Rather than one of the items offered by manufacturers of PC water-cooling gear, I choose to use the unit pictured below. I choose this particular filter for several reasons. It has 3/8" (10mm) barbs. It has zero metals used in its construction. It's cheap and readily available. It will filter out much smaller contaminants than a "mesh screen" type unit. I can see inside it. It is very large (greater surface area = minimal restriction at the relevant flow rates in the loop). I have installed the filter just upstream of my CPU block (but hidden it behind my reservoir, as it is rather unsightly).

-

Forums first comp: CPUz Benchmark

ArchStanton replied to Storm-Chaser's topic in Benchmarking General

I am also sorry to hear that. Forgive my crass attempt at levity earlier. -

Forums first comp: CPUz Benchmark

ArchStanton replied to Storm-Chaser's topic in Benchmarking General

Oh, but you can. You need it because Mrs. Fox is so "hot" that without a sufficiently powerful cooler she'll be destined to spend all her waking hours on her back, or knees, or whatever position Mrs. Fox finds most amenable for amorous activities? -

Makes one wonder if his secret ambition is to have a heart attack and die at his post during a concert. If so, I hope he gets his wish. It would be an awesome way to go out. We have a customer whose father was a lifelong square-dancing enthusiast (not my bag, but hey). After his (the father's) wife had passed away, he would still spend every weekend on the dance floor. At 93 he did have a heart attack doing what he loved and actually managed to wink at the lady he had been dancing with before drawing his last breath. Indeed . These boys seem somewhat depressed about it, but they are quite good none the less .

-

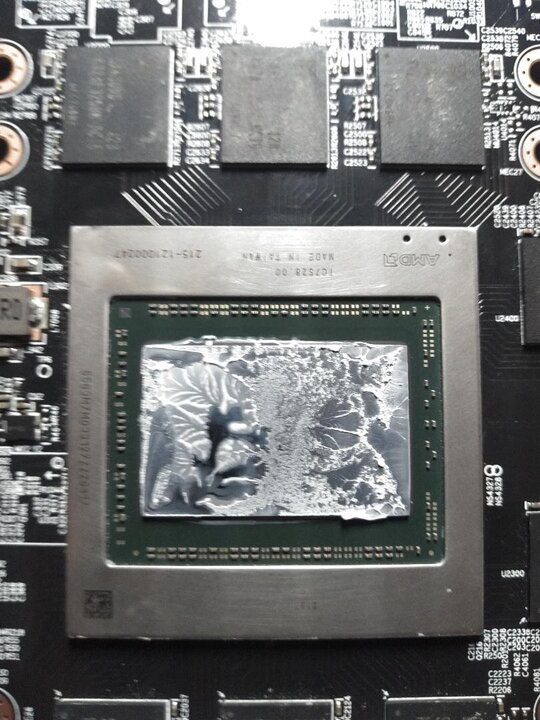

I did go ahead and tear her all the way down. The paste on the GPU looked like it had some voids. It also appeared like it had possibly been silk screened onto the waterblock during assembly. The VRMs had a thicker grey putty on the waterblock side and nothing on the backplate side. These little strips that look like pads are about as resistant to deformation as "play-doh" that's been left out a couple hours too long, but they will still ball up. The backside of the GPU die had a 3mm thick square pad between itself and the backplate. I went ahead and replaced the stock paste with MX-5, the grey putty and 3mm pad with TG-PP10, and, since TG-PP10 has a limited shelf life (or claims to, not sure how it can go bad if properly stored, but whatever), I used the remainder on the backplate side of the VRMs. It may be of little benefit, but better there than expiring in the little bottle it came in. For my first open GPU surgery, I am pretty pleased (assuming I have a video signal when I finish reassembling the rest of the system) .

-

When I need a reminder that there are people out there who can actually play an instrument. When I need a reminder that no matter how good you are, somebody somewhere someday will do it better.

-

Comments by you and others both here on this forum and elsewhere convinced me it was some handy stuff to have around. Got a little 50g jar from Digi-Key about a week ago to have around for a rainy day .

-

Overclocking 6900xt vs undervolting, reminds me of vega64 a bit

ArchStanton replied to Minotaurtoo's topic in AMD

I'm a complete overclocking novice, so unfortunately, even though I am also the owner of a 6900 XT, I have no insights to share with you other than to provide a link to a thread over at OCN that I've read a substantial portion of in preparation for squeezing what I can out of my own GPU. [Official] AMD Radeon RX 6900 XT Owner's Club | Overclock.net. You may already be fully aware of this thread. If so, I'm sorry I was unable to be of assistance.- 1 reply

-

- 1

-

-

Forums first comp: CPUz Benchmark

ArchStanton replied to Storm-Chaser's topic in Benchmarking General

@Mr. Fox Amazing. Something with multiple pastel shades that doesn't make me want to blow chunks all over my keyboard. Well done I say! -

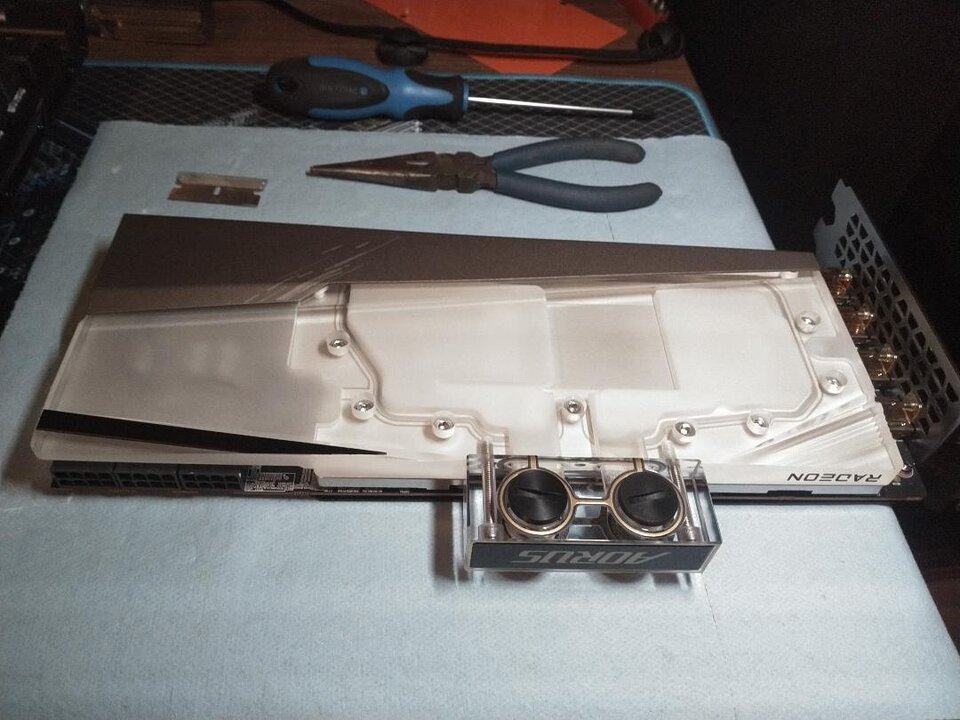

Curiosity got the better of me last night, and despite my initial misgiving I decided to investigate the state of the GPU more thoroughly. I was somewhat pleased to discover that in a dark enough room with a directable light source one can get a decent view underneath the reflective foil backed translucent plastic cover (provides that oh so cool mirror shades effect that convinced me to buy the card in the first place.../end sarcasm) that Gigabyte decided they should glue to the acrylic top. Those ZMT slivers are pretty small though, and I wanted a better view. So, razor blade + plastic dish scraper + patience = items preventing access to the acrylic top retention screws removed without any significant permanent damage (heat gun would have probably helped as well). Now let's clean all of EKWB's gunk out of my poor baby. Except there wasn't any gunk inside the GPU...Either my bi-directional flushing had already removed the material, or, more likely I think, the "micro" channels in the block are so much larger and coarser than those present in the upstream CPU block that anything managing to pass through the CPU block wasn't going to get trapped here. Anyone know what this says? I haven't the faintest idea. Prior to purchase, I had read a few comments to the effect that the leak detection system could be overly finicky. If I ever need to disable it doing so would be relatively simple. With a ridiculous amount of patience, cotton swaps, Scott towels, and Goo Gone, I have managed to clean about half of the adhesive off the acrylic top . I will do battle with the remaining half tonight, as I have decided I'll keep the "mirror" plastic without reinstalling it at this time. I confess I was surprised I didn't encounter more issues than actually arose. The little I had previously been able to find regarding taking this exact card apart had given me the impression that things would break, things would be irreparably marred, things would need to be hidden under a PSU shroud to prevent one's friends and neighbors from booing and hissing as one passed them one the street. Thankfully, such is not the case. At this point I'm slightly tempted to continue the teardown and inspect the factory thermal compound spread and or thermal pads, maybe replace the pads with some of that fancy putty I've been seeing bandied about. Who knows .

-

I realized I forgot to answer this query. They really didn't. I explained the issue and my testing as best I could while filling out the form to submit the claim. A few days later I received an email with an attached shipping label. A few days after I shipped it, I received another email indicating that yes, they could replicate my results in their tests, and they would be shipping me a replacement. A day or two after the replacement arrived (today) I received an email request to take a survey that I plan to complete shortly. Edit: The hyperlink to take the survey is broken .

-

I'm sure the CPU will be fine, for that matter, the original would probably have been fine with a positive CO offset on core 1. I think their automated curve generation system (the system that generates the default core rating and v/f offsets and writes said info somewhere inside the contents of the IHS) is far from perfect and picks the wrong core(s) from time to time. I doubt the average DIY PC enthusiast would ever have known the CPU wasn't just as it should be. I wouldn't have 5 years ago. It took a very specific "artificial" load to expose the instability it had. I was on the fence regarding RMA, but ultimately decided that given what I paid for it, they (AMD) ought to at least be expected to make another attempt providing a little higher quality sample than the one I originally received. Sadly, I just don't see the effort required to release more than a single 3D version of Zen3 worth it for AMD with Zen4 waiting in the wings. It might be worth it if Zen3 quit selling a week after Alder Lake launched, but it doesn't feel like that happened. Sometimes I daydream about a 5950X with TWO high grade CCD's instead of one strong and one weak. Marketing would be a cake walk with a model designation of something like 5950 XXX or 5975 X². It's a childish (for me) but appealing fantasy . Also, thank you for the feedback on the GPU(s). I'll take another look, but I think the GARX6900XTXWWB16GB has a cover intended for maximum diffusion of ARBG LED's, and as such, the "frosting" severally inhibits the viewing the internals of the block.

-

I did thoroughly flush each 10' section that I bought with about an 80psi source for several minutes (and then rinse with DI water), but obviously that isn't sufficient if the slivers aren't originating at the barb-tube interface .

-

Thank you for the tip ! Rather than Zero Maintenance Tubing, it is actually "Extra Maintenance Tubing". I was unaware .

-

The replacement CPU has arrived, so I plan to start reassembling everything this weekend. In the interim, I tore the loop completely down and thoroughly inspected/cleaned everything with the exception of the GPU. I suspect the process of accessing the internals of a Gigabyte Aorus RX 6900 XT Xtreme Waterforce WB 16GB (* stupid long name) would/will void the warranty. In hindsight, even though I obtained a 6900 XT with factory waterblock for $1,500, knowing what I know now, I would have bitten the bullet and gone a different direction. I'd would have gotten something a lot less "proprietary". I was extremely pleased with how easy it was to access and clean the internals of the Heatkiller IV CPU cooler. On that score, I found a significant number of very small pieces of EKWB ZMT caught in the microchannels. We're talking tiny little slivers of that black "rubber". Hairlike in nature, and maybe 1/16" long at most. My best guess as to their origin is that they are being cut from the parent piece of ZMT when I slide it over the barbs on the EK-Quantum Torque 6-Pack STC 10/16 - Nickel – EK Webshop (ekwb.com). The fit is tight enough without the retention collar installed that I cannot imagine the pressure produced in the loop to be sufficient to dislodge the tubing from the barb. However, I will NOT be testing this particular hypothesis, as I can imagine heat cycling "inch-worming" the tubing off over time. I am concerned about these same slivers of ZMT possibly also being present in the GPU block, but to date, I have only flushed it multiple times in both directions. Maybe I'll crack her open and maybe not. I am still debating it. As previously mentioned, I intend to do some comparative testing between various versions of D5 pump. I now have the requisite gauge, test port fitting, etc for pressure measurements. The adapter fitting I needed to connect the gauge to the test port fitting was supposed to arrive today, but sadly the fitting I received from a 3rd party on Amazon (sold by ^&@#, shipped by Amazon) was in no way correct. For that matter, they shipped me a quantity of 5 of the wrong fitting. To their credit, Amazon is taking them back no questions asked and refunding my CC when UPS gets it to the appropriate warehouse. This is the exact fitting I require: 4-4BSP | Lenz (lenzinc.com). Sadly, Lenz appears to be the only manufacturer of these that I can find, and they don't do retail sales, only wholesale to a distributor. So, Motion Industries, the closest distributor to me, plans to send me a couple in two weeks. I guess not even Lenz itself keeps them on the shelf. C'est la vie .

-

Odd. I always thought that Micron/Crucial should have an advantage in the DRAM market since, similar to Intel, they had their own fab facilities, but that hasn't always worked out for Intel either . I realize Micron hasn't indicated they are vacating the DRAM market, but it still feels strange for them to EOL their flagship product series without immediately announcing a "successor" product.

-

Tangential, but I thought it might be mildly interesting. Here are a pair of mobile hydraulic QD's. These would be okay for circuits up to about 10gpm. Their rated working pressure is 4350psi with a burst pressure of 7000psi (female) and 17,000psi (male). The pressure drop across the union at 13.25gpm would be about 150psi. Most circuits (loops) would be using 2 pairs of these, so that 150psi pressure drop x 2 would equate to a about 1762W (about 2.25hp) of power being wasted (mostly as heat either radiated away by the couplers themselves or transferred by the oil to an oil cooler).

-

@J7SC_Orion Any particular brand of ethernet cable you prefer? Or do you possibly make your own?

-

I'm not an expert, as you are already aware, but from my limited experience, any fitting "painted" or "plated" a particular color isn't going to hold that color well unless handled extremely carefully (little bits will flake off even when tightened or loosened by hand). So, I might suggest picking the brand/style of fitting you like best (assuming availability) and then being prepared to paint them all to match, with the option to repaint/touchup in the future (assumes you pick a readily available and consistently colored paint). The Bitspower's you linked last appear to be straight up polished brass to me, no "coloring" whatsoever. For some reason, the naked brass finish appeals to me the most.

-

To me, your crimps look factory, which isn't easy on something as small as 26AWG (for me at least). Hence, why I was curious to see your particular crimper. I use something very similar, but I don't normally have to contend with anything smaller than 18AWG regularly. Again, bravo on both your craftsmanship and photography skills .

-

Interviewing the Forum: How and why did you begin using folding@home?

ArchStanton replied to damric's topic in Folding@Home

I have not participated to date, though joining this forum has convinced me to learn more about it and possible crunch some proteins in the future. -

May we see your crimper of choice? That is some quality work .

-

Disclosure: I received the item in question as a free promotion related to the purchase of some additional water-cooling supplies from an online retailer. I have not allowed this attempted bribery to color my opinions in the slightest. I will be as biased and unfair as I feel inclined at any given moment. Furthermore, those who lack the innate ability to detect poorly constructed satire should stop reading and consider blocking the author. Normally I begin my reviews of a product with an "unboxing/packing section". However, as this particular item effectively functioned as piece of packing foam for the items I ordered, I think I will skip that portion of the review and proceed directly to documenting my test apparatus, which suits me fine as I am not compensated on a "per word" basis. Testing equipment: Two relatively large and somewhat abused human hands that are accustomed to frequent and strenuous manual labor. If you've previously seen "Sin City", these are what Marv referred to as his "mitts". The product itself is rather unpretentious. You may have noticed what appears to be a flaw in the outer casing, but that would be an incorrect assumption. The port in question is actually a required feature for anyone who can't crack walnuts with their bare hands. The port detailed in the above picture allows air to enter and leave the unit's interior when the product is being used in the manner intended by the manufacturer. However, the foam from which the bulk of the item is constructed is of sufficient density that I find the product to have the opposite of the desired effect. After squeezing it 5 times in as many seconds I found myself more stressed than when I began. Obviously, I cannot recommend this product be used for its intended purpose since, for me, it had the opposite effect. While receiving the product did not directly involve any fiduciary outlay by me, I feel that the design is sufficiently bad to justify a "Aww, hell naw" rating none the less. Edits: for spelling and grammar

-

So, as I was twiddling my thumbs waiting for the RMA process to complete, I realized my hydraulic test kit at work likely contained a G 1/4 test fitting. Low and behold, it did. I'll need to acquire a low-pressure gauge to have decent resolution (smallest of my existing is 0-50 psi). I think I'll pick up something in the 0-10 psi range. So, I should be able to provide both pressure and flow readings in the not-too-distant future .