Welcome to ExtremeHW

Welcome to ExtremeHW, register to take part in our community, don't worry this is a simple FREE process that requires minimal information for you to signup.

Registered users can:

- Start new topics and reply to others.

- Show off your PC using our Rig Creator feature.

- Subscribe to topics and forums to get updates.

- Get your own profile page to customize.

- Send personal messages to other members.

- Take advantage of site exclusive features.

- Upgrade to Premium to unlock additional sites features.

-

Posts

495 -

Joined

-

Last visited

-

Days Won

33 -

Feedback

0%

Content Type

Forums

Store

Events

Gallery

Profiles

Videos

Marketplace

Tutorials

Everything posted by Mr. Fox

-

From the album: Mr. Fox's Rigs

-

That is exactly what I was going to suggest trying first. This is a common problem with Windows 10 and 11. Sometimes resetting the Windoze icon cache will correct it. Winaero Tweaker has a couple of features for this that you can try.

-

-

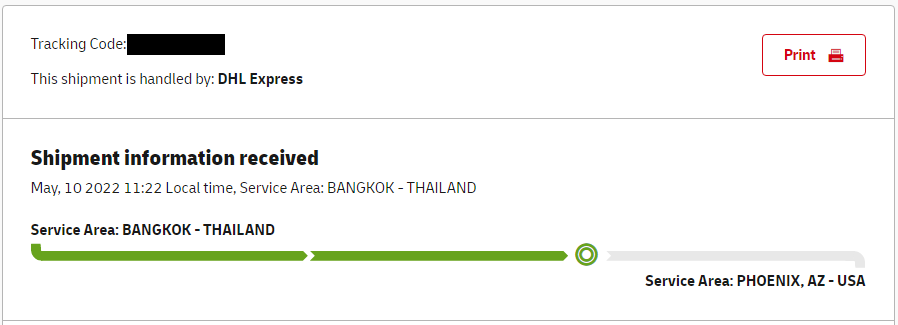

That is great news. I still do not have my tracking info yet. I have asked for it. Since I received a reply on Friday that DHL would have it later that evening, I waited until Monday and asked where the tracking number is. Did they update your order on the web site or send you an email with the tracking number? How did you receive it?

-

The problem is the abuse of power and taking of freedom. Bad leaders/politicians allow power to go to their head and they anoint themselves as gods to make far too many decisions they have no business making. It might be crypto today, but overclocking and high performance computers and fast cars tomorrow.

-

I am surpised the eBay listing did not specify the material, especially given that it is stainless steel. That's awesome. No, sadly he did not. He only said DHL and he has not updated my order information. Status remains the same as the day I bought it.

-

Those look great. Sometimes the nicest things are the simplest. I can't tell from the photos or the eBay listing what they are made of. It looks like aluminum. Is that correct?

-

He finally replied and said it would be given to DHL today, so we will both likely see it soon. I thanked him for the updated and told him I was excited about receiving it. I think the sun might be setting on this hobby for me soon as well. It is getting too expensive and not as much fun as it used to be. I don't mind a challenge now and then, but doing something for pleasure starts losing its shine when it so much of it becomes difficult due to deliberate interference.

-

The inside of that has a very clean and organized look to how it is put together.

-

Mine has had that same status since the day the order was placed. If you are on the order history/summary screen (at least on mine) it says "Preparing for shipment" but when you drill down to the order details it shows what you see. I see it is "out of stock" so we definitely jumped at the right time. He probably makes them to fulfill orders rather than having stock on hand. That would be my guess. Otherwise, there would be no reason for it not to have already been shipped a week ago. I am not worried about not receiving it and I am OK with the idea of him making them to fill orders because it is tough running a small business and investing in product ahead of demand. I'd be content and gladly accept that as a legit response if it is accurate. The part that bugs me is not the delay, but the ignoring messages from a paying customer. I know they were read because I saw confirmation they were, but the guy is just choosing to ignore me. Maybe that is common for their culture, but I don't appreciate it from anyone, including Rockitcool and OptimusPC (both of which also have a reputation for ignoring customers for at least long enough to make them unhappy with the poor service and lack of urgency in communication). But, I digress. We put up with crappy customer service when there are no competitors for a niche product. Because we want it, and can't get it anywhere else, we put up with it when we wouldn't tolerate it otherwise.

-

Any word on your order from Supercool yet? Still nothing here yet. And, they don't respond to messages

-

Ask Alexa. She can tell you if your fruits and vegetables are clean. Best way to be sure is to shower daily, using soap and water.

-

Indeed. I do remember being disappointed that I had no email. Now I am disappointed about how much email I get. And, 99% of it is unsolicited crap that I wish I didn't get. My how things change. One might say that you can get too much of a good thing, but in the case of email it is generally too much of a bad thing.

-

I can remember saving my money to upgrade from a 14K modem to 56K. Rich people and some businesses had a T1 line if they lived in an area that supported data transmission rates "that fast" LOL. I remember swiping a credit card in a store and waiting for the cash register modem to dial up to complete the transaction.

-

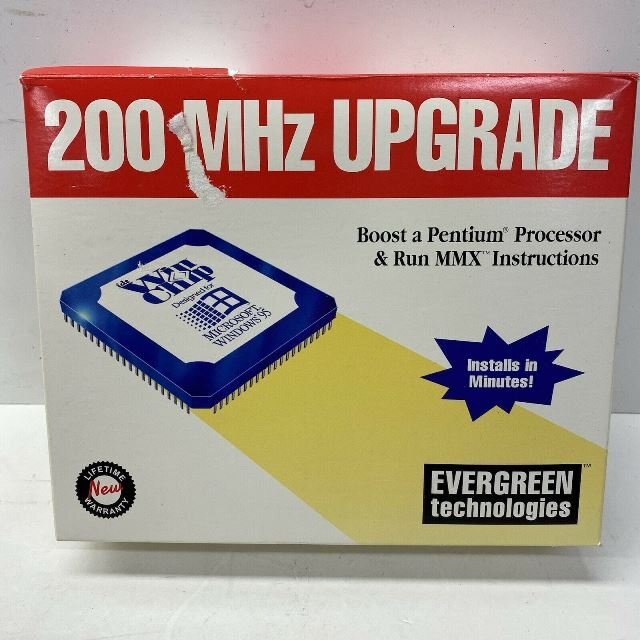

I can remember being excited about my first VGA monitor and being stoked about upgrading from an 8088 CPU to a 486SX. It took me a long time to embrace Windows. Real men used DOS. Windows was for wusses and Mac-lovers. Edit: I also remember adding a math coprocessor as an upgrade to speed things up... And, there was a company called Evergreen Technologies that sold AMD CPU upgrades with an adapter for the CPU socket to fit an AMD K5 100MHz (yes, 100, and 1 core/1 thread "upgrade" kit) processor onto an Intel mobo. That was long before the internet was invented, LOL. https://www.cpu-world.com/CPUs/K5/index.html https://www.cpu-upgrade.com/CPUs/AMD/K5/AMD-K5-PR100ABQ.html Later came the 200MHz bombshell upgrade to end all upgrades.

-

My kids felt lucky. Each had their own custom desktop PC built by daddy on the 6-computer home network. Laptops were rare back then. They cost a small fortune and were generally used exclusively for business. Laptops back then were beige putty colored like most desktops and monitors, and many had a built-in trackball, before touchpads were invented. We spent many weekends "killing" one another in frag matches in Quake II, Unreal Tournament, Arena, etc. They cut their teeth playing QBasic Nibbles and Bananas using a CRT display and MS-DOS, (I think before Windows was invented, although my memory of that is a bit foggy now,) but that quickly morphed into Commander Keen, Wolfenstein 3D, Doom back when Apogee/id software were brand new companies at the forefront of PC gaming. Everything then was on 3.5 inch floppy disks and optical drives were brand new tech that almost nobody owned yet.

-

Midtown Madness, Monster Truck Madness and Motocross Madness were among the games that spent many hours entertaining my 5 kids. In fact, just last week one of my sons mentioned how much fun those three were and the good memories he had of the family playing them. He specifically remember ramming houses with a monster truck and everyone giggled about the old man voice yelling "hey you kids, get off my lawn!!" LoL Anyone else have memories of spending hours on dial-up, braving sketchy web sites hunting for No-CD cracks and trainers so you could leave your CDs in their jewel case? Little kids were murderers of CDs. The kids had a knack for scratching them up. My custom builds always had two optical drives so I could burn disposable "working" copies of new discs using Nero and Slysoft AnyDVD and CloneCD/DVD on the DRM-protected discs. That way the originals stayed like new.

-

That is way cool. Where did you get the mod? I will look into that. I stopped playing it because it could not hold my interest. I am almost exclusively a First-Person Shooter gamer. It is rare that I enjoy playing games in other genres. On the topic of gaming, I just LOVE exposing all of the lies and gimmicks about Windows 10+ being needed to support gamerboy crap. Another fake system requirement exposed. Myth busted. Behold! Windows 7 with Resizable Bar support enabled and working. This was not because I care that much about the feature itself, I just wanted to show another example of the Redmond Reprobates being compulsive liars. DX12 is probably the most famous of their lies. It was the dangling carrot for Windoze 10 from the start, and we already have evidence that it works fine on Windows 7 except for the control-freak approach they have taken. Oh well, Vulkan is better anyhoo. It is funny that EVGA Precision X1 "assumes" the BIOS has CSM/Legacy mode enabled. It does not. GPU-Z, NVIDIA Control Panel and PX1 all show it is enabled.

-

Without something better to compare them to, they still look very good.

-

Those look great. I always do a really terrible job of choosing my cable combs. They always end up not working well (because they are either too large or too small for the sleeved wiring diameter) and end up being sloppy loose, or break because they are too brittle, mess up the sleeve because they are too tight, etc.

-

Indeed. It would sell like hotcakes on the internet, or on the impulsive buy-me shelves next to the checkout stands at Walmart and Target. And, there are a lot more "Space Cadets" today than there were when we were kids. They're just older cadets now. Sadly, they're allowed to breed and do other things that we'd all be better off if they couldn't do. I had forgotten about that helmet. Add it to the list of unforgivable denials of childhood, LOL. Seriously though... thank God our parents weren't stupid. That's more normal today that I would care to admit, but not as normal as some members of society would like it to be. It just makes the brainwashing so much easier with stupid parents.

-

The two things I still haven't forgiven my parents for not allowing me to order are X-ray specs and SeaMonkeys. I mean c'mon now... what 3rd grader doesn't need those things. They had to work. Every magazine had advertisements for them.

-

100%. Sometimes (often) I think smartphones are one of the most diabolical inventions known to man. Not the dumb device itself; it's exactly that--a dumb device. But, the way is it secretly exploited for nefarious purposes. There is no doubt in my mind that it will be a gateway to things that would make us squirm/vomit/go postal if knew what was coming later, or if we knew what was happening now that we're completely oblivious to. As they say, ignorance is bliss. Ditto all the above for the internet. Amazing tools in the hands of bad people, unaccountable and self-anointed to be the ones in control.

b.thumb.png.0bbda2ec32c1a1aa86fc47d4201e73d3.png)